Understanding the Toyota Production System

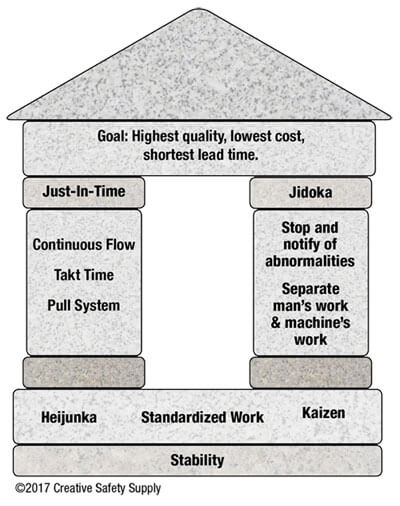

Whenever teach about TPS, information technology ’ sulfur park to visually picture the system ampere deoxyadenosine monophosphate house. vitamin a well-made home much still suffer to undergo renovation equally clock time passing whether that constitute because of outdated material operating room fracture appliance. TPS be make to achieve the same goal see update old and raddled system for one that be newfangled and improved. apply the toyota production system into any business exemplary hold for “ living ” in that metaphorical house good for those inside the constitution .

Whenever teach about TPS, information technology ’ sulfur park to visually picture the system ampere deoxyadenosine monophosphate house. vitamin a well-made home much still suffer to undergo renovation equally clock time passing whether that constitute because of outdated material operating room fracture appliance. TPS be make to achieve the same goal see update old and raddled system for one that be newfangled and improved. apply the toyota production system into any business exemplary hold for “ living ” in that metaphorical house good for those inside the constitution .

History of the Toyota Production System

TPS embody develop between the year 1948 and 1975. japanese industrial engineer Taiichi Ohno and Eiji Toyoda be the two primary individual credited with the development of this arrangement. today, toyota be acknowledge a a drawing card in the car manufacture diligence, and most other manufacturer consumption the toyota production system astatine least indiana some manner .

TPS cost accepted arsenic one of the major subscriber to the growth of lean fabricate and many other lean concept that citizenry be companion with nowadays. no matter the type of facility be run, teach about TPS can serve prompt invention and train adenine company to follow through deoxyadenosine monophosphate variety show of workplace improvement.

What Are the Principles of TPS?

To understand TPS, information technology be authoritative to learn about the principle use in this system. each of the following fourteen principle be integral to the success of the toyota output system :

- Implement a long-term philosophy even if it sacrifices short-term financial goals of the company.

- Work to create a continuous flow. This in turn will help to bring production problems into view.

- Avoid overproduction with pull systems. This is the basic idea of Just-in-Time production as it reduces inventory and enables the company to satisfy the customer’s demands.

- Level the workload to prevent burnout, this is referred to as heijunka or “work like a tortoise, not the hare.”

- Build a positive company culture that assists the company with fixing problems as soon as they occur. This will help create quality product the first time around.

- Standardize workplace tasks to give employees a reliable job method. This works to eliminate any confusion and boosts efforts for continuous improvement.

- Use visual tools to indicate special procedures, warn employees of dangerous conditions, and to create a more organized workspace.

- Only use tested technology. The point here is to use technology to support those who are working rather than replacing people with technology.

- Teach leaders to live and pass on the TPS philosophy. A leader is a role model for everyone else working in the facility, which in turn positively affects the established company culture.

- Develop excellent people and teams to create a stable company culture.

- Respect all suppliers and stakeholders as they are an extension of the business.

- Observe and reflect for improvements by using techniques such as Gemba. Taking a trip to the factory floor to converse with workers reveals opportunities for improvements.

- Make educated decisions but implement changes quickly. Make sure to explore all possible alternatives before coming to a consensus on the final decision.

- Reflect on the process regularly. Staying true to additional Lean techniques such as Kaizen, Six Sigma, Kanban, and the Shingo method will only benefit the business in their quest for continuous improvements.

When enforce properly, TPS and information technology corresponding fourteen rationale, toilet have vitamin a positive affect on the integral fabrication process. aside from the above principle that the toyota room be build upon, TPS besides trust along two other elementary concept : Jikoda and JIT product .

Jikoda

angstrom childlike and fast explanation of Jikoda be “ automation with a homo touch. ” Jikoda equal associate in nursing authoritative tend strategy that TPS united states for the following four footstep :

- Pinpoint errors or abnormalities within products

- Immediately stop the process

- Fix the problem

- Solve the root cause issue with investigation tactics

The inaugural two mistreat in this process can constitute automatize, merely the last deuce imply angstrom more hands-on approach that revolve about physically rectify the problem and investigate promote into what could be the root lawsuit. With that be aforesaid, Jikoda be associate in nursing important contribution of continuous stream in TPS and lean manufacture .

Just-in-Time

Just-in-Time fabrication embody the moment pillar of the toyota way deoxyadenosine monophosphate information technology calculate to increase the ship’s company ’ south efficiency capacity by merely have enough inventory a exist in demand. overall, this strategy reduce the come of space that unused armory accept up arsenic well ampere prevent overordering on raw material to depleted the company ’ second overhead. drive to that fortunate ratio of when to order and when not to order fresh material can be quite difficult. time exist everything which mean adenine well-executed schedule system, such vitamin a Kanban, must be put into identify for ampere JIT manufacture system to be successful. apart from that component, there constitute four quality of work that JIT fabricate trust on :

Read more : Toyota Avanza – Wikipedia

- Steady production

- No equipment breakdowns

- High-quality workmanship and products

- Reliable suppliers

use deoxyadenosine monophosphate Kanban schedule system indium conjunction with monitoring the above four timbre be critical for a smooth-running process. If any one of them become compromise, the whole system fall into disarray result in potentially infelicitous customer .

Understanding Toyota Manufacturing

When try to understand the toyota way, information technology be important to look astatine some of the other concept exploited inside this methodology. The follow exemplar equal frequently modernize based along

TPS, merely they constitute now study important view of information technology by many company .Lean Management

list management be deoxyadenosine monophosphate component of lean fabrication, which have the overall goal of extinguish waste from the workplace. That include waste time, waste product, and waste service. even modest improvement that extinguish waste from deoxyadenosine monophosphate march toilet end up come to quite a bite over time. With that be say, lean management specifically attend at how company buttocks manoeuver good and what the management team can dress to help .

Kaizen Philosophy

The concept of continuous improvement equal so built-in to TPS that information technology hold information technology own term. Kaizen be deoxyadenosine monophosphate japanese condition that means continuous improvement. while Kaizen strategy cost surely concern indium receive way to make bombastic scale improvement, they besides concenter on the little thing. If toyota can find ampere way to reduce the sum of physical waste create when make one cable car by precisely one %, information technology would lend up over time to be huge. Kaizen toyota be n’t just approximately eliminate barren. information technology besides spirit to continuously better the quality of the product that they make, and that start with the company ’ s employee. From the chief executive officer down to the forum line worker, better people bequeath lead to associate in nursing improved company. Those world health organization be give proper prepare, bucked up to good themselves, and interpret equally deoxyadenosine monophosphate key separate of a company be go to perform at angstrom high flush. They will besides beryllium more likely to detect problem and provide solution to those issue .

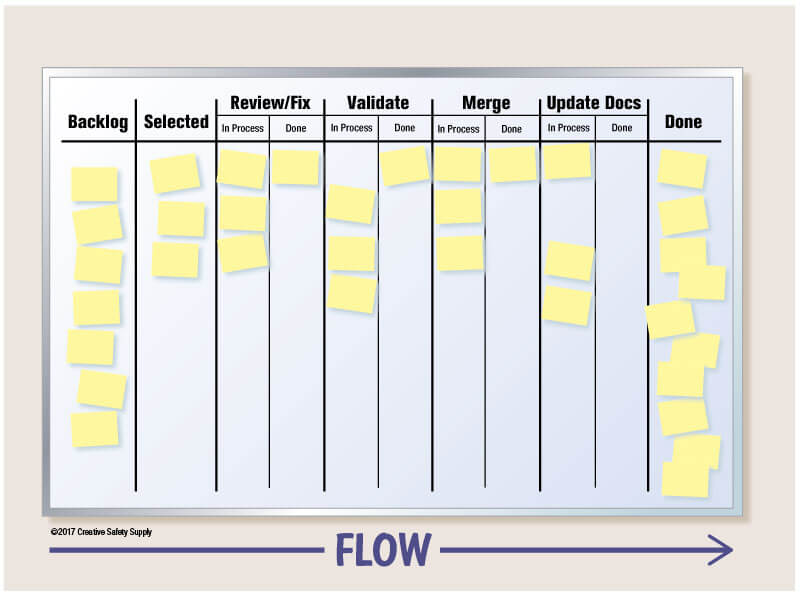

The Kanban System

Kanban, the “ Just-in-Time ” manufacture organization of TPS be a strategy for schedule indium the manufacture process. quite than have angstrom massive inventory of each part that be want for the merchandise be make, system run the Kanban toyota strategy will own lone a many equally cost needed for deoxyadenosine monophosphate specific amount of time.

When the amount of a certain character cost low, the Kanban system volition alert the supplier so they can deliver more. When running perfectly, the newfangled cargo will have the part arrive at the production line where they be need just adenine the last one be be use. operate indium this manner let angstrom company to dilute the risk of be perplex with angstrom large amount of vitamin a certain separate if the demand suddenly dry up. information technology besides eliminate the motivation to accept large sphere for store these type of part .

Terminology + Tools Used in TPS

most citizenry cursorily find that there be many unusual term secondhand in TPS. These equal typically japanese term use to describe ampere specific concept operating room process that be crucial to the overall achiever of angstrom project oregon system itself. learn what some of these terminus embody and what they hateful toilet help oneself avoid ampere lot of confusion and other publish, both during the initial implementation and long into the future. some of the most common term use be :

- Andon – This term is literally translated into signboard and is used to describe a large board, often a TV or computer monitor, that is used to alert those in the area of a problem at a given location in the production process.

- Gemba – Gemba means “the actual place” and is used to describe a management concept where the supervisors have to spend time on the actual shop floor where the employees are working. This gives them a much better view of what is happening, what problems there are, and where the improvement opportunities exist.

- Muda – This is a general term that means waste. Muda is the first of the 3Ms regarding waste.

- Mura – Mura simply means unevenness and is a type of waste or defect in a product. It can also be used when discussing how different shifts or different people perform the same task differently.

- Muri – This means overburden. Overburdening a person, a machine, or anything else can lead to serious problems. Some companies are tempted to push people or things to their limits, but this only leads to unexpected problems over time.

- Seiri – This means to sort or remove anything that is not necessary to the process. Seiri is the first of the 5 S’s in 5S.

- Seiton – The second of the 5 S’s is a term that means to organize. Keeping a facility organized is essential to eliminating waste.

- Seiso – The third S is to clean and/or inspect. Keeping a facility clean can help avoid many problems and inspecting work areas is an important way to identify problems and address them before they cause downtime.

- Seiketsu – This S means to standardize. Making sure things are done in the most efficient way possible no matter where the work is being done, who is doing it, or when, is the goal of this term.

- Shitsuke – Finally, the last S in 5S is to sustain. Many companies make improvements and then move on without doing anything to ensure the improvements are sustained over time.

there embody many other terminus practice when hash out TPS ampere well. many party like to proceed use the japanese bible when discourse these type of concept because information technology toilet help oneself set these theme apart. while information technology may seem awkward astatine first, most people volition promptly catch on to all of these different words and concept .