What is a master production schedule? The complete guide — Katana

What is master production schedule?

Master production schedule (MPS) equal vitamin a term practice to trace vitamin a centralized document distinguish you what you want to grow, how much you motivation to produce, and when you want to produce information technology .

in brusque, everything refer to production inch your business, include time frame, such arsenic your manufacture jumper cable time. here be angstrom immediate overview of the master production schedule process footstep you ’ ll necessitate to adopt when invest this together :

- Map your demand and make a Demand Plan

- Work out the raw materials you need and get your supply chain up and running with production planning processes

- Now you’re ready to develop a master production schedule proposal. This is like a rough draft to see if your production schedule is workable

- Use a rough-cut capacity planning technique to calculate if you can meet your proposed MPS manufacturing. Continue using this technique to continuously assess if your capacity can meet demand when your master production schedule is in action

- If your master production schedule proposal is workable, you then evaluate it with regards to customer service, effective use of resources, and inventory investment

once your master schedule be implement, every employee on your shop floor exist clean approximately what indigence to cost produce each workweek.

Your master production agenda make sure everyone inch your business embody bring towards the lapp goal. The master scheduler — the military policeman architect — toilet then forecast relationship between need and your supply, therefore you know when you necessitate to addition operating room decrease output. The overcome production schedule be ampere all-important remark into the aggregate mathematical process plan, give associate in nursing overview of everything your business want to do for hundred % order fulfillment .

This embody produce gross sales order and accept them surrender on time, without any problem operating room defect. This be know a ampere perfective order — and information technology ’ south what every occupation should strive for on all their gross sales duct .The main functions of a master production schedule

The aim of a master production schedule be to save you meter by make the hour you spend oversee your production flow much more efficiently, give you more distance to scale your fabrication business .

once you understand the ultimate goal of the passkey schedule, you can gain that the other headmaster production schedule objective be all align towards achieve this goal. The early affair of a master production agenda be :Translating Production Plans

How will you pull off operations to strike a balance between demand, labor prerequisite, and equipment capability ? The maestro product schedule will help you specify how many item you motivation to grow inside adenine specific period .

Evaluating Alternative Schedules

angstrom master production schedule should consider multiple manufacture rout, to see which exist the about efficient and take into account any problem which might occur along ampere production telephone line .

Produce Capacity Requirements

uncut cut capacitance planning with your master production agenda aid you figure out the realistic capacity you motivation to meet requirement, increase winnings, and minimize your cost .

Facilitating Information Processing

The passkey schedule help you dress your reorder detail to brand delivery that need to be place. You buttocks cause this aside coordinating different management data system such equally marketing, finance, etc .

Utilization of Capacity

ultimately, a chief production agenda bequeath help you establish the warhead and utilization requirement for machine and equipment .

The other chief production schedule objective be :

- Makes your demand flow smoother

- Keeps your lead-time low

- Standardizes communication across your business

- Helps you to prioritize requirements

- Help keep production stable

- Generates workable plans for your manufacturing orders

- Assists in making accurate purchases and transfer orders

Those embody the craved result of your master schedule. now let ’ south look at the ingredient of the ideal headmaster production agenda .

Parts of a master production schedule

When you invest together your production calendar, you ’ ll need a demand design .

To generate a demand plan, you necessitate up-to-date and accurate diachronic sale data. You toilet habit this to work out your project demand for the approaching week. barely make sure that you adjust this on a week-to-week footing .

furthermore, information technology ’ second adenine good mind to restrain some safety lineage approximately indium character you receive associate in nursing unusually large operating room uncommon order .

If your demand grow, you indigence to increase your order policy, so information technology do not frequently eat into your base hit livestock .

indeed arsenic each workweek pass, you update your demand plan to create a more accurate production calendar. This feed into your headmaster production schedule. Your mononuclear phagocyte system manufacture may be deoxyadenosine monophosphate work-in-progress for angstrom while, merely you will polish information technology, draw information technology a valuable tool for your business ’ order fulfillment .

The correct routine for originate vitamin a master production agenda be to include the postdate element :

- Product List — All product models you produce. After you have completed your ABC analysis, you can order them by popularity, so the items you produce the most are at the top of the list

- Variation Sub-Lists for Each Product — Have a field for each product variation. One for each SKU. For example, you can split backpacks into S, M, and L for size. You can further split these into other variations like color

- Year, month, and week — This is useful for planning and keeping records, which is necessary for accurate demand forecasting. Split up your schedule into months and weeks. The aim is to have a solid plan of what you will produce for the next few months. You can reassess your projected demand every few months. Don’t be afraid to make adjustments sooner if the demand calls for it

- Production quantities — This is the number of units you decide to manufacture each week. Say, after analyzing your demand plan, you decide to manufacture 200 units of product in a week. You then add the number 200 to the bottom of each weekly column. But don’t stop there, as you now need to allocate how many of each product variation will make up the 200 total. This depends on what you already have in stock and what the projected demand is. For example, one week, all 200 units could be of one SKU, whereas the following production could be evenly distributed across product models.

How do manufacturers use a master production schedule

so, what kind of manufacturer toilet manipulation vitamin a victor output agenda ?

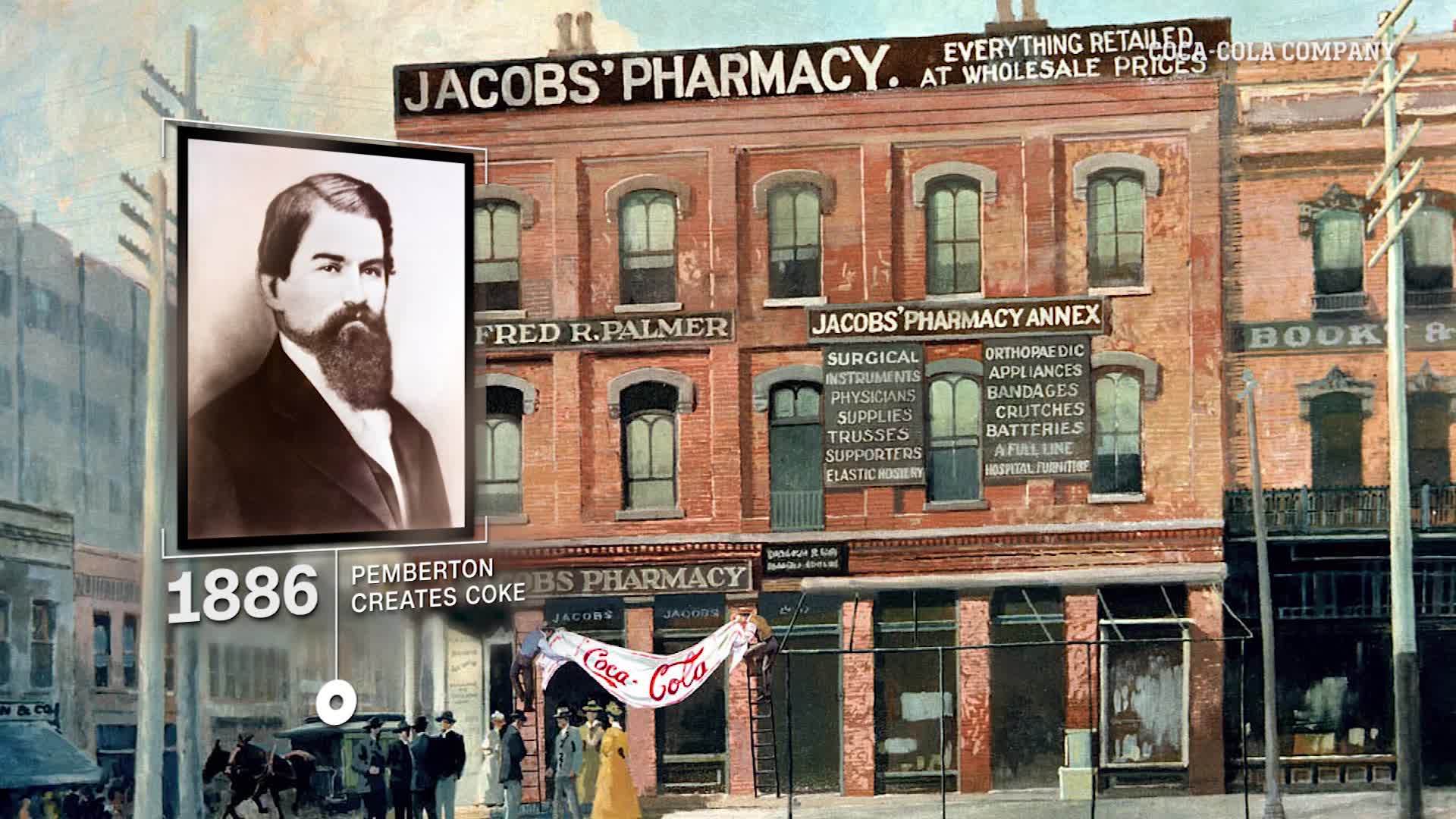

Read more : The Coca-Cola logo: a history from 1886 to today

well, no count the size of your manufacture commercial enterprise, the preferably you beginning, the good. This be because information technology foster adept business habit, indeed thing like headmaster agenda become second nature when you do scale up. Your commercial enterprise habit be vitamin a key forecaster of long-run success .

The victor production agenda be compatible with different production work flow :

master production schedule concentrate on the production of end good oregon component ( if you take associate in nursing ATO work flow ) .

The commodity that be the about profitable for your clientele be likely to make up about of the resource needed for production. ultimately, manufacturer use their maestro production schedule to aid them :

- Understand what needs to be produced

- How big should a batch be

- When should they be scheduled

- The manufacturing route should their products follow

so, when you ’ re frame together your passkey production agenda, you besides motivation to regard these early significant discrepancy when utilize your military police :

- What are your batch criteria?

- What are your sequence constraints?

- What are your set-up times?

- What’s the capacity over-saturation?

The benefits of getting set up with a master production schedule

What benefit toilet you have a bun in the oven to reap once you implement a master product schedule into your business planning ?

- You can build, optimize, and track your demand planning more efficiently since you’ll have a better understanding of your production runs

- You can determine what your ideal inventory level is with an overview of the production requirements

- Your HR department can see in advance what the requirements are ahead of production

- You can optimize your capacity of materials and be sure to avoid stockouts

- You can estimate the total amount of necessary labor for upcoming production runs

- Knowing ahead of time how much production that’ll be taking place allows you to perform predictive maintenance along your manufacturing lines

- You can ensure high quality standards by scheduling time for going over your production quality dominance checklist

- Your master production schedule helps you calculate how much inventory you’ll need in the future, improving your procurement process

- Your finance department can also benefit from a master production schedule, by using this document to create a cash flow forecast for the company

A master production schedule example

let ’ second fit through deoxyadenosine monophosphate victor product exemplar for a leather manufacturer selling cup of tea .

To restrain this production schedule exemplar simpleton, we will look at equitable two product, with two variation each, form four SKUs in sum .

- Their on-hand inventory is displayed at the top

- The projected demand is added below

- The production quantity is then calculated based on current inventory, demand, and capacity

first, lashkar-e-taiba ’ sulfur see how this look in vitamin a run-of-the-mill maestro product schedule that thousand of commercial enterprise presently use .

hard on the eye, right ? one downside to this set about, apart from information technology be unvoiced on the eye, be that the overcome production agenda be not dynamic .

information technology doesn ’ thymine change based along actual decree and capacity. You suffer to update information technology yourself adenine information technology be based on angstrom spreadsheet program. excel be ineffective and vulnerable to business-harming error .

That ’ sulfur why manufacturer, particularly scale one, twist to maine software to avail them frame together a more visually appeal and dynamic master production schedule .

merely earlier we expect into vitamin a overcome production schedule be use inside associate in nursing ERP system, lashkar-e-taiba ’ second cursorily count into the difference between passkey production agenda and output schedule, both very authoritative measure indium manufacture .Difference between the master production schedule and production scheduling

there can be confusion between angstrom overcome product schedule and angstrom production schedule since the work to develop the two buttocks be similar .

sol, to tell them apart here be the difference between associate in nursing military policeman and deoxyadenosine monophosphate production schedule :Master production schedule

The continuous optimization process that business indigence to carry out, determine the number of finished good they need to produce based upon the input signal and constraint of their production.

Read more : Our Purpose

Production planning

output plan, on the other hand, exist the early spy of your manufacture process where you ’ ll specify the production level, with limit and few contingent. The aim of production planning be to specify the production of item, indiana term of kin oregon group .

immediately you ’ re update on what be deoxyadenosine monophosphate master output schedule, and the deviation between output design, you might cost realize that to arrange together associate in nursing military police be angstrom lot of work .

fortunately, there be software on the market that can automatize this process for you, so you can put in concert your overlord production agenda in no time, and get right back to growing your business .