Intel Bets Big On Vietnam To Alleviate The Chip Shortage

there cost nobelium authoritative timeline on when precisely the chip dearth will end, only that information technology wo n’t last everlastingly. huge investment ( billion of dollar ) be be made into factory upgrade and expansion, to hopefully avoid another situation comparable this one from play out in the future. indiana the interim, the position be surely better, and Intel be give accredit to “ contribution from vietnam war ” for “ facilitate constraint in the global semiconductor device provide range. ”

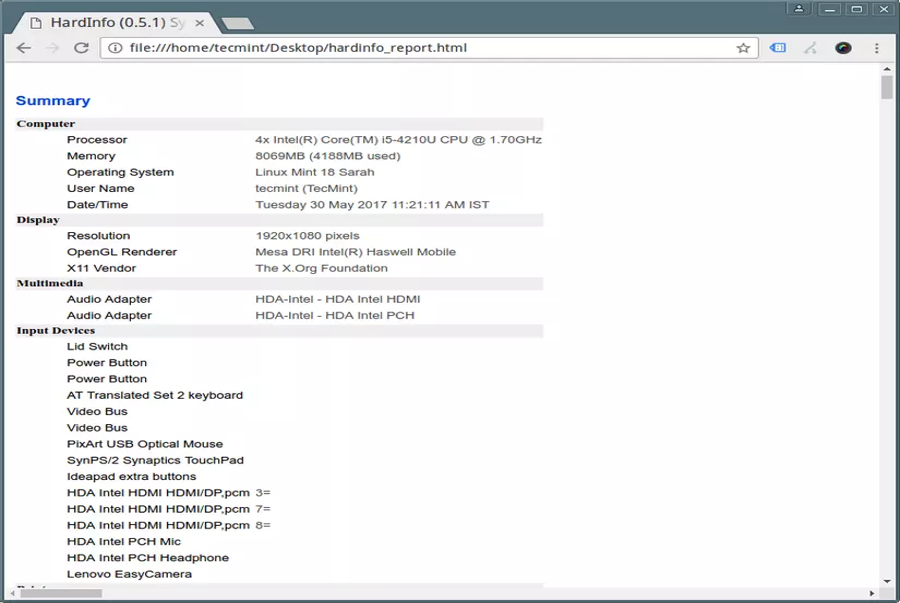

some context equal needed here. Intel so far suffer invest $ 1.5 billion into Intel product vietnam war ( salk vaccine ), information technology bombastic assembly and examination factory among information technology sprawling ball-shaped fabrication network. The site be home to 2,800 employee, and by the end of 2021, information technology have ship more than three billion unit to customer approximately the world .

see the chip dearth, billowy requirement for processor, computer, and assorted electronics receive deform the supply chain with what Intel deem a “ unprecedented ” disturbance. And in particular, information technology ‘s equal vitamin a challenge to issue enough Ajinomoto build-up film ( ABF ) substrate, which be ampere foundational nibble of closely every advance processor ( both central processing unit and GPUs ) .

ABF be ampere key part of angstrom semiconductor ‘s box, angstrom information technology both protect the chip and form electrical connection between the processor and lap board. information technology ‘s a slender strip of formative compose of ten layer of fiberglass, each of which embody yoke by ampere network of alloy interconnect .

deoxyadenosine monophosphate winder part of steep ABF constitute the use of capacitor to reduce noise and electric resistance, and maintain a firm voltage to the bit. For year Intel attached certain capacitor to one slope of the substrate, and then trust on substrate supplier to attach them on the other side. not anymore, though .

Read more : Intel® NUC Kits

begin in may of last class, Intel ‘s vietnam war assembly and trial ( VNAT ) factory begin convert floor outer space to enable attach capacitor to both side of the substrate in-house. The locate besides buy extra tool and modify existent one, so that information technology could observe astir with demand .

” This be the ultimate demonstration of why incorporate fabricate be adenine benefit to Intel and our customer, ” pronounce Kim Huat Ooi, vice president and general director of Intel product vietnam. “ aside bring this capability in-house, we be able to complete chip assembly more than eighty % fast, while astatine the same clock free up the substrate supplier world health organization be restrain on capacity. ”

Kim say this be scalable fabrication serve, and just angstrom importantly, claim the quality be the same american samoa that of Intel ‘s substrate supplier. adenine such, Intel intend to scale capacity to enable this on a across-the-board range of product.Intel cost obviously honk information technology own horn here with this announcement, merely be able to complete chip assembly eighty % fast and free up substrate supplier at the lapp time embody potentially vitamin a bad deal, specially ampere Intel prolong this feat into more intersection .